Recently, a comparative study was carried out by Walther Stikvoort into the load capacity of saddle-supported horizontal pressure vessels. He compared the L.P.Zick method with the limit load-based method. One of the tools used in this study is the VES software developed by P3 Engineering.

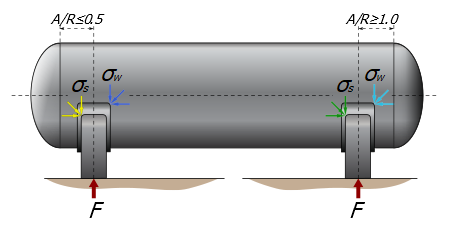

The assumption is that the stresses, caused by the support reaction, at the horn of the saddle are decisive. This is based on experiences with large thin walled horizontal pressure vessels supported by two symmetrically placed saddles.

- Rules for Pressure Vessels - NL

- ASME BPVC Section VIII - Division 1 and 2 (USA)

- PD 5500 (UK)

- EN 13445 (EU)

- AD 2000 (D)

Walther Stikvoort found that there are significant differences in the load-bearing capacity of the saddles depending on the saddle calculation method used. The largest difference occurs in the case of saddles placed near the ends when the L.P.Zick method is used. This is especially true when using a wear plate. Using the limit load-based method there is much less influence of the saddle location on the allowable saddle load. There is not much difference between EN 13445 and AD 2000

Finally, in the formulas for calculating the circumferential bending stress at the horn of the saddle according to L.P.Zick, inexplicable differences were found in the denominator of the formula. This observation has since been submitted to the relevant code committee of PD 5500. They reply that there is currently a subcommittee working on it.

The study by Walther Stikvoort was published in the American Journal of Engineering Research (AJER). See this link for the complete paper.